CAPABILITIES

With RW’s long time experience in product development and manufacturing, we are able to join new product design and development with our customers in early stage. In this way, many design issues can be resolved to avoid possible development and production problems. We use extensive FEA analysis to help evaluating designs such as converting a part form casting to forging or vice versa to reduce weight and cost.

|

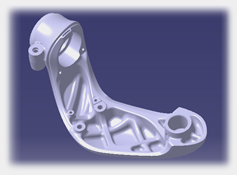

BeforeCasting 1.916kg A356 T6 Material Tensile Strength 284Mpa |

|

AfterForging 1.782kg 6061 T6 Material Tensile Strength 310Mpa |