INNOVATION

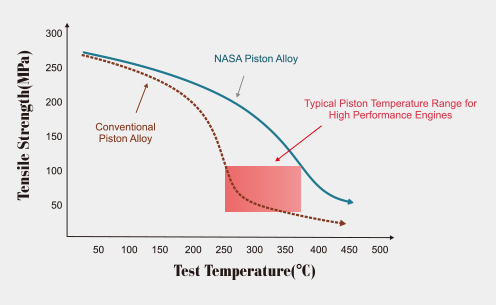

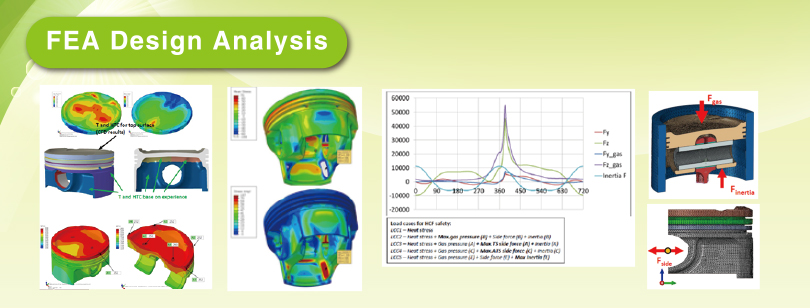

Right Way is proud to be the only piston manufacturer in the world that can make high quality cast pistons in conjunction with NASA for high performance engines. With NASA’s patented alloys and our experience, our pistons have extraordinary properties under high temperature which can make your piston more durable and lighter. Today, we produce more than 200,000 pistons annually using NASA alloys.

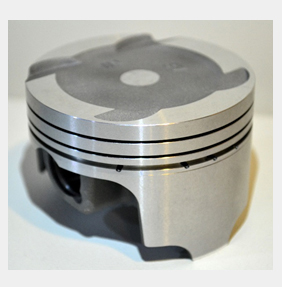

Recently, we apply our unique technology to make first NASA forged aluminum piston. The piston is under evaluation and we expect the performance will be even better than cast ones.

High temperature strength comparison between NASA and normal alloy |

NASA Alloy Forged Piston |

Characteristics of NASA alloyBreak-Through Heat Resistance & Fatigue Strength

Exceptional dimensional stability

Greatly Improved Wear Resistance

|

ApplicationIdeal for DI 2-stroke & 4-stroke Supercharged Engines

Substituted from Forging Piston

Suitable for Lightweight Piston Design

Raise Compression Ratio for Higher Performance

|